Top Warehouse Automation Challenges and How to Overcome Them

What is Warehouse Automation?

Warehouse automation refers to the use of advanced technologies and robotic systems to streamline and optimize various processes within a warehouse or distribution center. The primary goal is to enhance operational efficiency, reduce errors, and improve overall productivity in handling inventory.

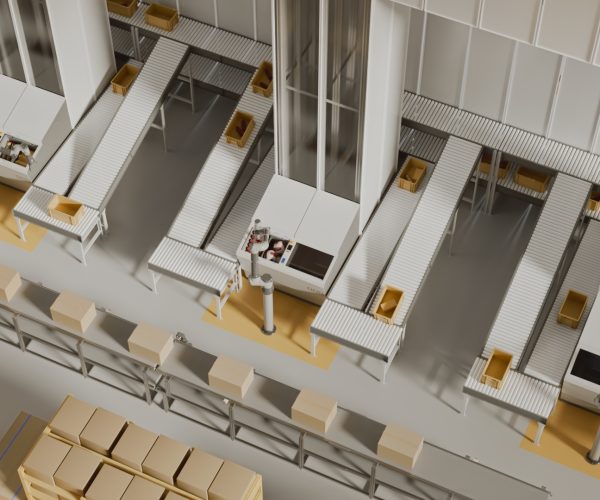

Automation in warehouses involves the implementation of technologies such as automated storage and retrieval systems (ASRS), conveyor systems, robotic arms, autonomous vehicles, and advanced software solutions for inventory tracking and management. These technologies work together to automate tasks such as picking, packing, sorting, and transportation of goods.

By leveraging these automated systems, businesses can achieve faster order fulfillment, minimize human intervention in routine tasks, and respond more effectively to the demands of the modern supply chain. Warehouse automation plays a crucial role in meeting the challenges of today’s dynamic market, enabling companies to stay competitive and adapt to the evolving landscape of e-commerce and global logistics.

The Challenges of Warehouse Automation

In the ever-evolving landscape of modern logistics, warehouse automation stands as a pivotal solution to enhance efficiency, accuracy, and speed in handling the intricate processes of inventory management. However, implementing and maintaining a seamlessly automated warehouse system comes with its own set of challenges.

From the integration of cutting-edge technologies to workforce adaptation, and the continuous need for system optimization, businesses face a myriad of obstacles. Overcoming these challenges requires a strategic approach that combines technological innovation, meticulous planning, and a commitment to workforce development.

Navigating the complex terrain of warehouse automation demands a holistic perspective that not only addresses the technical intricacies but also acknowledges the critical role of human involvement in ensuring a successful and sustainable automated ecosystem. In this era of rapid technological advancement, unlocking the full potential of warehouse automation necessitates a proactive and adaptable approach to overcome the hurdles and revolutionize the way goods are stored, retrieved, and distributed.

The Most Common Challenges Faced in Automation

Warehouse automation, while offering numerous benefits, comes with its share of challenges that organizations must navigate for successful implementation and sustained operation.

High Implementation Cost:

One of the foremost challenges is the significant upfront cost associated with implementing warehouse automation systems. The initial investment in robotics, software, and infrastructure upgrades can be substantial, potentially posing financial constraints for smaller businesses. Overcoming this challenge often requires careful cost-benefit analysis, long-term strategic planning, and seeking innovative financing options.

Scalability:

The scalability of warehouse automation systems is another key consideration. As business operations grow or change, the automated solutions should be flexible enough to adapt to varying demands. Achieving scalability may involve selecting modular and easily expandable automation technologies, allowing for seamless integration of additional robotic systems or adjustments to accommodate evolving business needs.

Reliability and Maintenance

Ensuring the consistent reliability of automated systems is crucial for preventing disruptions in warehouse operations. Technical malfunctions or breakdowns can lead to downtime and impact productivity. Robust maintenance protocols, predictive maintenance strategies, and investing in high-quality, durable equipment are essential to mitigate these challenges and sustain the efficiency of automated processes.

System Integration

Integrating new automation technologies with existing warehouse management systems (WMS) and other software can be a complex task. Incompatibility issues, data synchronization challenges, and the need for seamless communication between different components are common hurdles. Establishing a comprehensive integration plan, often with the assistance of experienced consultants, is crucial to ensure smooth interoperability and data flow across the entire supply chain.

Lack of Expertise and Training

The successful implementation and operation of warehouse automation systems requires a skilled workforce that understands the intricacies of the technology. A shortage of expertise in robotics and automation can hinder the adoption process. Providing adequate training programs for existing staff and hiring individuals with the necessary skills can address this challenge. Collaboration with educational institutions and training organizations can also contribute to building a talent pool well-versed in automation technologies.

Addressing these challenges requires a strategic and comprehensive approach that encompasses financial planning, technology selection, system design, and ongoing training and maintenance. As businesses strive to reap the benefits of warehouse automation, a proactive and adaptable mindset is essential to overcome obstacles and maximize the long-term advantages of an automated warehouse ecosystem.

How to Overcome These Automation Challenges

Navigating the intricate landscape of automation in various industries will undoubtedly bring forth one, or a few, of the challenges mentioned above. Organizations looking to adopt automation must be able to or quickly learn to address these challenges so that they may unlock the full potential of technological advancements.

In this section, we will delve into pragmatic strategies and solutions on overcoming the most prevalent challenges in automation. From mitigating high implementation costs to ensuring seamless system integration, enhancing reliability and maintenance, and overcoming the shortage of expertise and training, we explore actionable insights that empower businesses to not only embrace automation but also thrive in the dynamic and evolving landscape of technological transformation. These approaches provide a roadmap for organizations seeking to harness the benefits of automation while effectively tackling the hurdles that may arise along the implementation journey.

1. High Implementation Cost:

Overcoming the challenge of high implementation costs involves strategic financial planning and creative funding approaches. Businesses can explore cost-sharing models, such as partnerships with automation providers or leasing options, to spread the financial burden. Conducting a thorough cost-benefit analysis helps identify areas where automation can yield the most significant returns, enabling companies to prioritize investments based on immediate and long-term benefits.

Additionally, phased implementation, starting with critical processes or departments, allows organizations to demonstrate the value of automation incrementally and generate early returns on investment, which can then be reinvested into further expansion.

2. Scalability:

Ensuring scalability in warehouse automation requires a forward-thinking approach. Businesses should choose a modular and flexible automation solution that can easily adapt to changing operational needs, much like AutoStore. This involves selecting technologies that allow for seamless integration of additional robotic systems or adjustments to the existing setup.

Establishing a clear roadmap for expansion and considering potential changes in product lines or market demands enables organizations to design scalable automation systems. Furthermore, forming partnerships with automation providers that offer scalable solutions and ongoing support ensures that the automation ecosystem can evolve alongside the business.

Regular assessments of scalability requirements and continuous monitoring of technology trends allow companies to proactively adjust their automation strategy, ensuring sustained efficiency as the organization grows.

3. Reliability and Maintenance:

Addressing challenges related to the reliability and maintenance of automated systems involves implementing proactive measures and leveraging technology to minimize downtime. Establishing a comprehensive maintenance schedule that includes regular inspections, preventive maintenance, and predictive maintenance using data analytics helps identify potential issues before they lead to system failures. Investing in high-quality, durable equipment and adhering to manufacturer-recommended maintenance procedures contributes to the overall reliability of automated systems.

Additionally, organizations can consider outsourcing maintenance to specialized service providers with expertise in automation technologies, ensuring timely and effective resolution of issues.

4. System Integration:

Effective system integration requires meticulous planning, collaboration, and the use of compatible technologies. Businesses should develop a comprehensive integration plan that considers the interoperability of new automation technologies with existing systems. Engaging experienced system integrators who understand the complexities of different systems and can create seamless connections between them is crucial.

Utilizing standardized communication protocols and application programming interfaces (APIs) facilitates smooth data flow between different components of the automation ecosystem. Regular testing and continuous updates are essential to ensure that all integrated systems function harmoniously, providing a unified and efficient warehouse automation solution.

5. Lack of Expertise and Training:

To overcome challenges related to a lack of expertise and training, companies must invest in workforce development and education programs. Designing comprehensive training initiatives for existing employees ensures they are well-equipped to operate and troubleshoot automated systems. Collaborating with companies that specialize in educational services to create specialized training programs tailored to the organization’s needs helps address the skills gap.

Another creative solution would be strategic hiring and recruitment efforts focused on individuals with expertise in automation technologies that contribute to building a skilled workforce. Continuous learning opportunities, workshops, and on-the-job training programs are vital to keep employees updated on the latest advancements in automation, fostering a culture of adaptability and expertise within the organization.

Speak with a Professional

Deciding if Your Company is Ready to Take the Jump Towards Automation

It is important for you to think long and hard about whether automation is a suitable solution for your business. By thoroughly reviewing the most common challenges you will face when taking that first big step into the world of automation and, most importantly, how to overcome those challenges, you will already find yourself on the right path.

Now that we know what roadblocks to expect and how to avoid them, we can review when to make the leap!

The decision to incorporate automation in a warehouse is a critical strategic decision that often hinges on various factors within a company’s operational landscape. Generally, a company may consider automation when experiencing consistent growth in order volumes, necessitating an increase in operational efficiency to meet rising demand.

If manual processes prove to be a bottleneck, leading to errors, delays, or inefficiencies, automation becomes a compelling solution to enhance accuracy and throughput. Additionally, companies with a diverse product range or seasonal fluctuations may find automation advantageous in adapting quickly to changing SKU requirements and order patterns. A need for improved traceability, inventory control, and real-time visibility into warehouse operations can also drive the decision to automate.

Moreover, when labor costs are escalating, and there is a shortage of skilled workers, automation provides a viable alternative to augment the workforce. Successful integration of automation often aligns with a company’s long-term growth strategy, enabling it to stay competitive, optimize resource utilization, and meet the evolving demands of a dynamic market.

In essence, the decision to automate a warehouse is a proactive response to operational challenges and an investment in future scalability and efficiency.

Conclusion

In conclusion, the journey towards warehouse automation, while rife with challenges, offers a transformative path for businesses aiming to revolutionize their operational efficiency. As highlighted in this exploration of the top warehouse automation challenges and their solutions, strategic planning and adaptability emerge as critical allies.

- Overcoming high implementation costs demands financial acumen, phased approaches, and innovative financing models.

- Scalability hinges on flexible technologies, modular solutions, and proactive adjustments aligned with business growth.

- Ensuring reliability and maintenance involves a commitment to robust protocols, preventive measures, and strategic partnerships for specialized support.

- System integration requires meticulous planning, leveraging standardized communication protocols, and collaborating with experienced integrators.

- Addressing the shortage of expertise and training necessitates a holistic investment in workforce development, education, and strategic recruitment initiatives.

The final “challenge” so to speak is deciding whether your business stands to benefit from automation which, in our expert opinion, is usually the case!

As organizations embrace these strategies, they not only conquer the challenges posed by warehouse automation but also pave the way for a future where the synergy between technology and human expertise propels businesses to new heights. In navigating these challenges, companies not only streamline their warehouse operations but also position themselves at the forefront of innovation, ready to meet the dynamic demands of the modern supply chain landscape.

The era of warehouse automation beckons, and with strategic insights, businesses can navigate the hurdles and unlock unparalleled efficiency, accuracy, and agility in their operations.