Online pharmacy Apotea boasts the world’s first robot piece-picking solution integrated with AutoStore

Sweden’s leading online pharmacy, Apotea, places high demands on its warehouse to quickly, easily and smoothly deliver approximately 50,000 orders a day to its customers. The successful AutoStore automation system from Element Logic significantly strengthens the maximum capacity. For the first time, automation is being installed for the entire process, including the unique eOperator piece-picking robot that works around the clock together with AutoStore.

Pharmacy products are one of the fastest-growing e-commerce industries in the world. Apotea.se is Sweden’s largest online pharmacy, with the country’s most comprehensive range of over 24,000 over-the-counter products and almost 16,000 prescription drugs for humans and animals. Since the start in 2012, sales have increased from approximately EUR 1.1 million to EUR 450 million. The company has also received various prizes and awards, including being named Sweden’s favourite online store (PostNord) in 2017, 2018, 2019, 2020 and 2021.

Watch the video from Apotea’s logistics center:

The industry’s leading customer experience

Apotea strives to provide the industry’s and e-commerce’s best customer experience, where expectations are exceeded through pleasant and simple shopping that appeals to existing and new customers. A central part in achieving this is fast and accurate deliveries, which start from Apotea’s logistics centre in Morgongåva business park, six miles west of Uppsala. The facility, which was inaugurated in 2018 and is 38,000 square meters in size, ships around 1 million packages every month. During 2022, the company has had a major automation.

“Apotea is an online pharmacy, and our business concept is fast deliveries, an extensive range, and that we deliver free of charge. Fast, cheap and free shipping says a lot about what we do here. And that’s what our customers think is important. We send out approximately 50,000 packages daily,” says Pär Svärdson, CEO at Apotea.

“Fast, cheap and free shipping says a lot about what we do here. And that’s what our customers think is important. We send out approximately 50,000 packages a day.”

Meeting the challenges with AutoStore

During the pandemic, Apotea’s demand increased quickly, and the massive and ever-increasing orders placed great demands on the company’s logistics centre. To solve this, Apotea has invested in automation from Element Logic, which takes care of the entire process – from in-bound delivery to out-bound delivery, via an AutoStore system, eOperator and additional functions.

The installation includes 20,000 bins (with space for a total of 25,000), 30 AutoStore robots (R5) and four carousel ports, three of which are served by eOperator piece-picking robots. .The goal is to optimise delivery, increase efficiency, and better cope with large variations in order intake that can occur over time. Apotea’s new installation is a collaboration between Element Logic, AutoStore, RightHand Robotics, and Apotea. In December 2022, all CEOs and founders from the respective companies met at Apotea’s logistics centre in Sweden to inaugurate the system.

“During the pandemic, we looked at expanding the capacity to go from delivering 50,000 orders to 100,000 orders. That’s when we thought of Element Logic and AutoStore. When we started looking at installing AutoStore, it was precisely the combination of being able to robotise the piece-pick that was one of the driving forces. It was essential to get the kind of solution we wanted, but also to feel that we got a solution that will be very effective for us,” says Pär Svärdson.

“When we started looking at installing AutoStore, it was precisely the combination of being able to robotise the piece-pick that was one of the driving forces.”

“To Apotea, the automation solution of AutoStore, eOperator and other features from Element Logic goes splendidly with their combined targets of optimal warehouse efficiency and environmental care. We look forward to following Apotea’s journey towards highly accurate deliveries along with saved energy, reduced noise levels and ergonomically friendly working hours,” says Dag-Adler Blakseth, CEO at Element Logic Group.

A scalable solution that is easy to integrate

AutoStore is a modular and scalable robotic solution for storing bins of products extremely efficiently. After picking from AutoStore, the order goes directly to delivery or back to be filled with additional products. Compared to a manual warehouse, picking performance is ten times higher with AutoStore. The system consists of a grid where robots pick and deliver goods on the smartest available routes in the grid, calculated by the control unit. The robots work around the clock and recharge themselves when needed. The robots move the bins around, and the software controls the bins’ content. The picked goods are delivered to the operator at the ports for further handling. Apotea’s logistics centre seamlessly integrates this with the other automation zones. Initially, the new capacity at Apotea is estimated to be 800 order lines per hour.

“To us, it was important to have a system that can handle variations in product size and order intake, and that can expand as we grow. This investment helps us become more efficient, which makes it easier for us to exceed our customers’ expectations,” continues Pär Svärdson.

“This investment helps us become more efficient, which makes it easier for us to exceed our customers’ expectations.”

The piece-picking robot eOperator – a unique solution

The installation of eOperator means that Apotea is investing in the world’s most advanced piece-picking robot, making them pioneers internationally in having robots picking from an AutoStore. eOperator picks automatically 24/7. Through machine learning, eOperator automatically selects the best way to handle an item to pick from AutoStore, which increases order capacity, goods handling, and delivery time.

“To us, the delivery time is important. eOperator enables us to deliver quickly to customers, even at night and over weekends. With this, we have managed to get a 24-hour operation that is absolutely exceptional. We get greater productivity and faster deliveries, making everything cheaper and more efficient. It became natural to say, yes, let’s do this,” continues Pär Svärdson.

“When we started talking to Element Logic about running AutoStore with robots, they saw that we would have a return on investment. We get greater productivity, faster deliveries, everything becomes cheaper and more efficient. Then it became natural to say; yes, let’s do this.”

“Apotea is an impressive giant in Swedish e-commerce. Since one of their main selling points is fast and accurate deliveries, it was natural to connect their AutoStore solution with Element Logic’s smart piece-picker, eOperator. The result is improved order capacity, goods handling, and delivery time,” says Anders Bohlin, Sales Director at Element Logic Sweden.

Sweden’s most sustainable e-commerce wants to lead the development

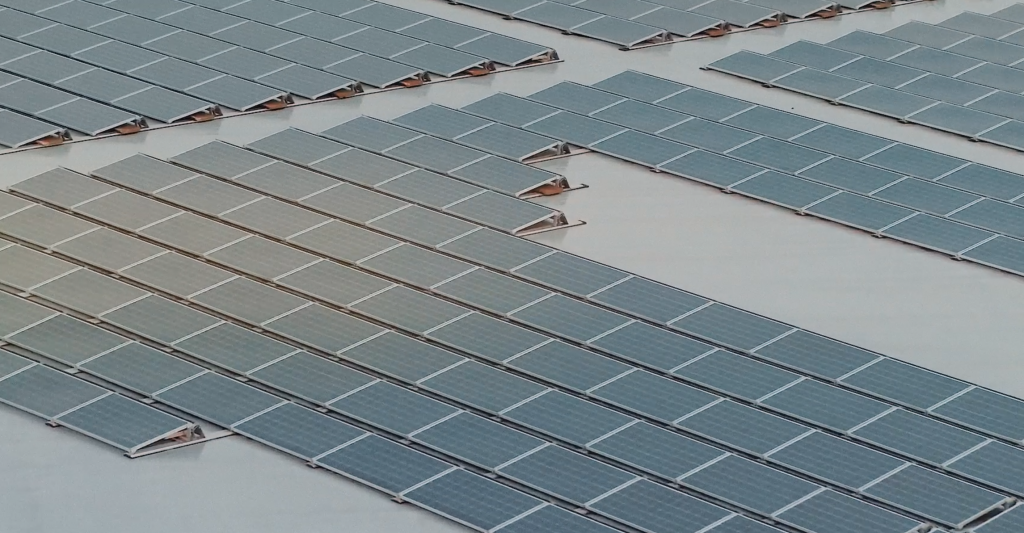

Apotea is not only the Swedish market’s leading online pharmacy but also Sweden’s most sustainable e-commerce, according to the Sustainable Brand Index 2020 and 2021. It has received the award for Sustainability of the Year by PriceRunner 2022 and voted Sweden’s most sustainable e-commerce company in PostNord’s consumer survey 2021. Apotea’s goal is to reduce the climate footprint through the entire chain, from production to end consumer. The logistics facility is environmentally certified as a green building with a Silver rating. In addition, you will find one of Sweden’s largest solar cell facilities on the roof of the logistics centre, which supplies the entire AutoStore system. The facility comprises 5,560 solar cell modules covering an area of 9,100 square metres. It provides a capacity of 1.5 MW, which is equivalent to what 70 houses consume in a year or what is needed to drive an electric car 230 times around the world.

“Our goal is to become Sweden’s most sustainable company, which is both bold and ambitious. It is important for humanity and our environment, but also to be competitive because I believe that future customers will demand a different approach to sustainability from companies than what is done today. We have one of Sweden’s largest solar cell installations on the roof, and the solar panels meet almost all of our energy requirements,” explains Pär Svärdson.

“… I believe that future customers will demand a different approach to sustainability from companies than what is done today.”

A more inspiring workplace

According to Pär Svärdson, installing AutoStore in Apotea’s logistics centre not only means saving space, reducing costs, and increasing warehouse efficiency. The company also develops the employees’ workplace, providing increased status and stimulation for the operators.

“Several of our employees have this as their first job, and many of them are young. I think it is a great developing process using a working model where you start with a manual job and then learn about technology to work with robots. You learn a lot going from lifting packages to becoming a robot operator,” concludes Pär Svärdson.

See the video from Apotea’s logistics center:

Facts about Element Logic’s installation at Apotea:

- 20,000 bins (with space for a total of 25,000)

- 30 AutoStore robots (R5)

- 4 carousel ports

- 3 piece-picking robots (eOperator)

- 800 order lines per hour (calculated capacity)

- 24/7 operations